Effect of in series and in parallel flow heater configuration of solar heat system for industrial processes

DOI:

https://doi.org/10.55225/sti.315Słowa kluczowe:

solar thermal, industrial processes, in series, in parallel, process heatAbstrakt

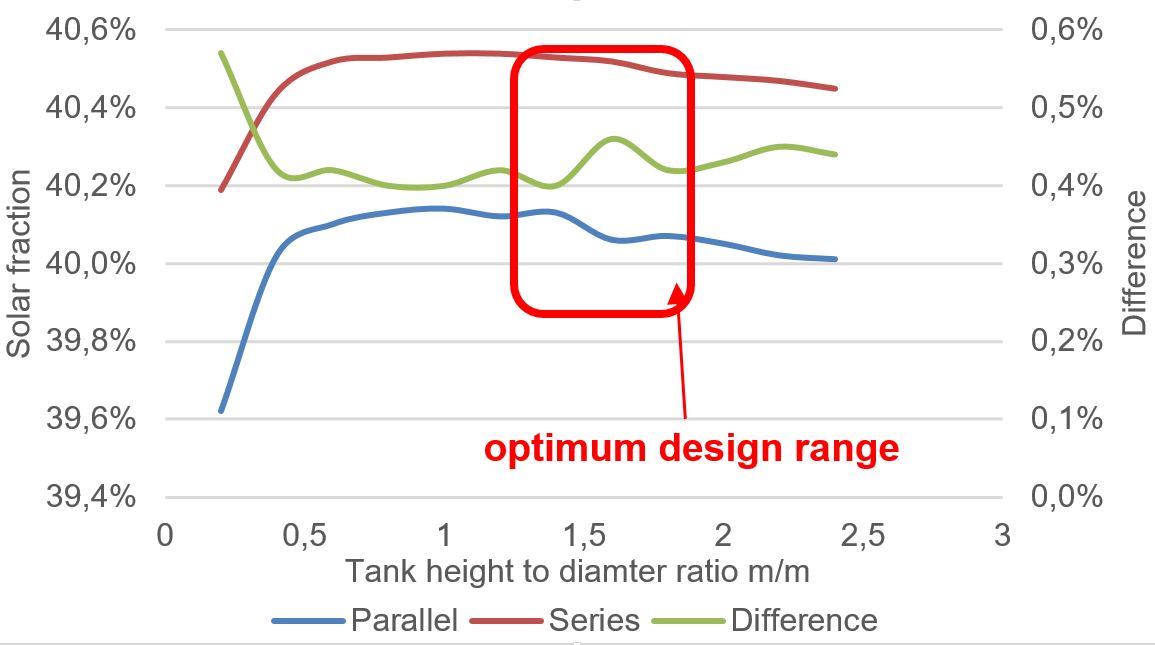

The boiler is an enclosed vessel that transfers the energy from fuel combustion or electricity into hot water or steam. Then, this hot water or pressurized steam is used for transferring the heat to a certain heat process. Usually, the required hot water or steam keeps on varying throughout the day which also may be implied on the daily or monthly load. Therefore, several configurations of connecting the boiler into the solar heating system ensure the temperature of the final output. The boiler can be connected in series or parallel to improve the efficiency of the overall process as well as to reduce the running costs. This paper presents a simulation study of a solar heating system for industrial processes. Two flow-heater system configurations are designed for covering the heat demand of a pasteurising factory existing in Budapest, Hungary. The configuration “A” consists of a solar heating system for hot water preparation using in series flow heater configuration. While configuration “B” consists of the same solar system but with a parallel flow heater configuration. These system configurations are modelled using T*sol software for evaluating the system performance under the Hungarian climate from five different aspects: required collector area, glycol ratio, volume flow rate, relative tank capacity, and tank height-to-diameter ratio. According to the optimum design parameters, in series configuration is better than parallel by 3.14% at 45 m² collector area, 0.45% at 25% glycol ratio, 0.42% at 50 l/h · m² volume flow rate, 2.05% at 50 l/m² relative tank capacity, and 0.42% at 1.8 tank height-to-diameter ratio respectively. The results show that in series configuration is better in terms of solar fractions than parallel configuration from all five aspects.

Statystyka pobrań

Bibliografia

Gautam A, Chamoli S, Kumar A, Singh S. A review on technical improvements, economic feasibility and world scenario of solar water heating system. Renewable and Sustainable Energy Reviews. 2017;68:541–562. https://doi.org/10.1016/j.rser.2016.09.104. Google Scholar

Benli H. Potential application of solar water heaters for hot water production in Turkey. Renewable and Sustainable Energy Reviews. 2016;54:99–109. https://doi.org/10.1016/j.rser.2015.09.061. Google Scholar

Kempener R. Solar heat for industrial processes: Technology brief. IEA-ETSAP and IRENA; 2015. https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2015/IRENA_ETSAP_Tech_Brief_E21_Solar_Heat_Industrial_2015.pdf. Google Scholar

Benécs J, Hermanucz P, Dodog Z. Applying of Intelligent Measuring System (IMRe) in food refrigeration. In: Piroska V, László M, editors. XIX. International Conference Risk Factors of Food Chain 2018. Book of Abstracts. Mátrafüred: Szent István University Publisher Nonprofit Ltd; 2018. p. 17. Google Scholar

IEA. Key World Energy Statistics 2017. Paris: International Energy Agency; 2017. https://doi.org/10.1787/key_energ_stat-2017-en. Google Scholar

Martínez CIP. Energy efficiency developments in the manufacturing industries of Germany and Colombia, 1998–2005. Energy for Sustainable Development. 2009;13(3):189–201. https://doi.org/10.1016/j.esd.2009.07.001. Google Scholar

Capuano L. International Energy Outlook 2020 (IEO 2020). Washington, DC: U.S. Energy Information Administration; 2020. p. 1–7. Google Scholar

MOSPI. Energy Statistics 2020. New Delhi: Central Statistics Office, Ministry of Statistics and Programme Implementation Government of India; 2020. Google Scholar

Zhou N, Levine MD, Price L. Overview of current energy-efficiency policies in China. Energy Policy. 2010;38(11):6439–6452. https://doi.org/10.1016/j.enpol.2009.08.015. Google Scholar

Vannoni C, Battisiti R, Drigo S. Potential for Solar Hear in Industrial Processes. Madrid: CIEMAT; 2008. Google Scholar

Abdelaziz EA, Saidur R, Mekhilef S. A review on energy saving strategies in industrial sector. Renewable and Sustainable Energy Reviews. 2011;15(1):150–168. https://doi.org/10.1016/j.rser.2010.09.003. Google Scholar

Hasanuzzaman M, Rahim NA, Hosenuzzaman M, Saidur R, Mahbubul IM, Rashid MM. Energy savings in the combustion based process heating in industrial sector. Renewable and Sustainable Energy Reviews. 2012;16(7):4527–4536. https://doi.org/10.1016/j.rser.2012.05.027. Google Scholar

Sharma AK, Sharma C, Mullick SC, Kandpal TC. Solar industrial process heating: A review. Renewable and Sustainable Energy Reviews. 2017;78:124–137. https://doi.org/10.1016/j.rser.2017.04.079. Google Scholar

Vignarooban K, Xu X, Arvay A, Hsu K, Kannan AM. Heat transfer fluids for concentrating solar power systems: A review. Applied Energy. 2015;146:383–396. https://doi.org/10.1016/j.apenergy.2015.01.125. Google Scholar

Benoit H, Spreafico L, Gauthier D, Flamant G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renewable and Sustainable Energy Reviews. 2016;55:298–315. https://doi.org/10.1016/j.rser.2015.10.059. Google Scholar

Moens L, Blake DM. Advanced heat transfer and thermal storage fluids. [Presented at the 2004 DOE Solar Energy Technologies Program Review Meeting October 25–28, 2004 Denver, Colorado]. Conference Paper NREL/CP-510-37083 January 2005. Google Scholar

Einstein D, Worrell E, Khrushch M. Steam systems in industry: Energy use and energy efficiency improvement potentials. Proceedings from the ACEEE Summer Studies Energy Efficiency in Industry. 2001;1:535–547. https://www.aceee.org/files/proceedings/2001/data/papers/SS01_Panel1_Paper46.pdf. Google Scholar

Pirasteh G, Saidur R, Rahman SMA, Rahim NA. A review on development of solar drying applications. Renewable and Sustainable Energy Reviews. 2014;31:133–148. https://doi.org/10.1016/j.rser.2013.11.052. Google Scholar

Muster-Slawitsch B, Muster-Slawitsch B, Schmitt B, Krummenacher P, Helmke A, Hess S, et al. Solar Integrating Solar Heat into Industrial Processes (SHIP) Booklet on results of Task49/IV Subtask B. vol. 10049. 2015. Google Scholar

Pag F, Jesper M, Jordan U, Gruber-Glatzl W, Fluch J. Reference applications for SHIP and renewable heat: Compilation of reference applications for integrated energy systems with solar heating plants incl. representative load profiles. International Energy Agency; 2021. https://www.iea-shc.org/Data/Sites/1/publications/210126_Task64_SubtaskA_D1-1_v2.pdf. Google Scholar

Horta P, Brunner C, Kramer K, Frank E. IEA/SHC T49 activities on process heat collectors: Available technologies, technical-economic comparison tools, operation and standardization recommendations. Energy Procedia. 2016;91:630–637. https://doi.org/10.1016/j.egypro.2016.06.217. Google Scholar

Sardeshpande V, Pillai IR. Effect of micro-level and macro-level factors on adoption potential of solar concentrators for medium temperature thermal applications. Energy for Sustainable Development. 2012;16(2):216–223. https://doi.org/10.1016/j.esd.2012.01.001. Google Scholar

Colangelo G, Favale E, Miglietta P, De Risi A. Innovation in flat solar thermal collectors: A review of the last ten years experimental results. Renewable and Sustainable Energy Reviews. 2016;57:1141–1159. https://doi.org/10.1016/j.rser.2015.12.142. Google Scholar

Iparraguirre I, Huidobro A, Fernández-García A, Valenzuela L, Horta P, Sallaberry F, et al. Solar thermal collectors for medium temperature applications: A comprehensive review and updated database. Energy Procedia 2016;91:64–71. https://doi.org/10.1016/j.egypro.2016.06.173. Google Scholar

Franco A. Methods for the sustainable design of solar energy systems for industrial process heat. Sustainability. 2020;12(12);5127. https://doi.org/10.3390/su12125127. Google Scholar

Duffie JA, Beckman WA. Solar Engineering of Thermal Processes. 4th edition. Chichester: Wiley; 2013. Google Scholar

Pobrania

Opublikowane

Jak cytować

Numer

Dział

Licencja

Prawa autorskie (c) 2021 Autorzy

Utwór dostępny jest na licencji Creative Commons Uznanie autorstwa – Użycie niekomercyjne 4.0 Międzynarodowe.