Mechanical behavior of particle-reinforced polyurethane composites for load-bearing drives

DOI:

https://doi.org/10.5604/01.3001.0013.6167Słowa kluczowe:

polyurethanes, composites, mechanical propertiesAbstrakt

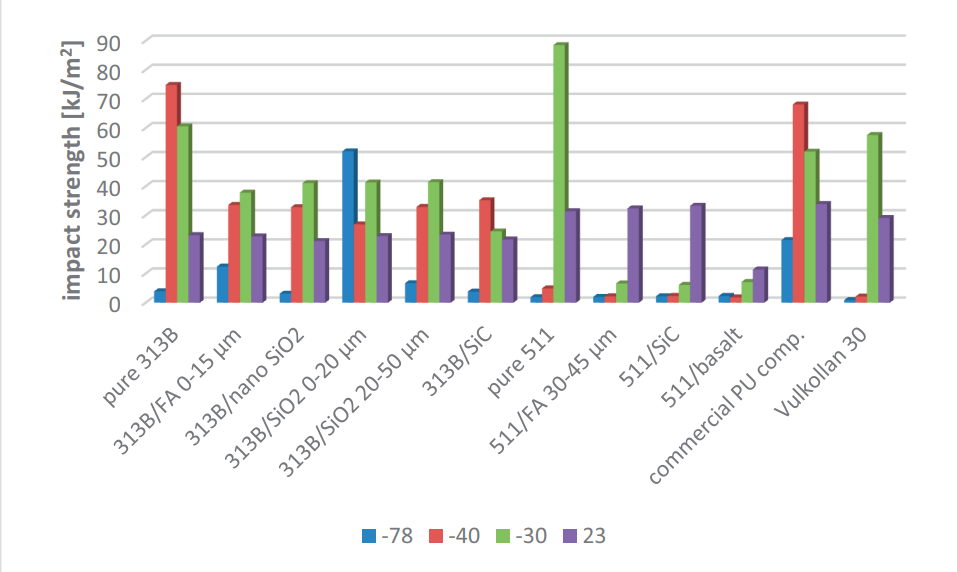

Two series of polyurethane composites were prepared using NDI- and MDI-based prepolymers and common polyol. NDI-based polyurethane is generally resistant to mechanical wear and rebound-resilient whereas MDI-based PU has cushioning and vibration damping features, and both types can be used as a matrix for load-bearing composites. The objective of this study was to compare the mechanical properties of composites containing 5% vol. of ceramic particles prepared with the use of the mentioned PU systems, and unmodified commercial materials. The effect of various ceramic particles on physical and mechanical properties was studied. The results showed that the mechanical properties changed in comparison to reference materials: E’ improved, and impact strength performed favorably in certain materials. Both the tensile strengths and the elongations at break of the composites were found to decrease with the content of ceramic particles; however, the hardness increased gradually. Since ceramic particles offer better stiffness and hardness, the selected composites could be a viable alternative to the pure commercial PUs available in the industry.

Statystyka pobrań

Bibliografia

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Nitthiyah Jeyaratnam Yuvaraj AR. Polyurethane types, synthesis and applications – a review. RSC Advances. 2017; 6: 114453-114482. Google Scholar

Atiqah A, Mastura MT, Ahmed Ali BA, Jawaid M, Sapuan SM, A Review on Polyurethane and its Polymer Composites: Current Organic Synthesis. 2017; 4: 233-248. Google Scholar

Shiferaw EW, Lule Z, Kim J. Thermal Conductivity and Mechanical Properties of Thermoplastic Polyurethane-/Silane-Modified Al2O3 Composite Fabricated via Melt Compounding. Polymers. 2019; 11(7):1103. Google Scholar

Su K-H, Su C-Y, Cho C-T, Lin C-H, Jhou G-F, Chang C-C. Effect of crosslinking on thermal and mechanical properties of polyurethanes. Scientific Reports. 2019; 9:14397. Google Scholar

Sair S, Oushabi A, Kammouni A, Tanane O, Abboud Y, El Bouari A. Mechanical and thermal conductivity properties of hempfiber reinforced polyurethane composites. Case Studies in Construction Materials. 2018; 8:203-212. Google Scholar

Xiong J, Zheng Z, Qin X, LiM, Li H, Wang X. The thermal and mechanical properties of a polyurethane/multi-walled carbon nanotube composite. Carbon. 2006; 44(13):2701-2707. Google Scholar

Junrui Z, Weiping T, Zilin D. Synthesis and characterization of transparent and high impact resistance polyurethane coatings based on polyester polyols and isocyanate trimers. Progress in Organic Coatings. 2012; 75:579– 583. Google Scholar

Sare IR, Mardel JI, Hill AJ. Wear-resistant metallic and elastomeric materials in the mining and mineral processing industries— an overview. Wear. 2001; 250:1–10. Google Scholar

Garrison TF, Kessler MR. Bio-Based Plant Oil Polymers and Composites. Oxford UK, Wolfram USA; Elsevier 2016. Google Scholar

Ryszkowska J, Auguścik M, Zieleniewska M, Szczepkowski L, Kurańska M, Bąk S, Antos-Bielska M, Prociak A, Semi-rigid polyurethane foams with rapeseed polyol of different viscosity, Polimery. 2018; 63(1):10-17. Google Scholar

Ed.: Thomas S, Datta J, Haponiuk JT, Reghunadhan A. Polyurethanes Polymers. Blends and Interpenetrating Polymer Networks. Amsterdam, Oxford, Cambridge; Elsevier 2017. Google Scholar

Zhang F, Javni I, Bili O, Bili N, Zoran S. Petrovic, Jan Ilavsky. Eur. Polymer J. 2015; 64(11):1607-1616. Google Scholar

Fernández-d'Arlas B, Baumann RP, Pöseltd E, Müller AJ. Influence of composition on the isothermal crystallisation of segmented thermoplastic polyurethanes. Cryst. Eng. Com. 2017; 19: 4720–4733. Google Scholar

Zhou SX, Wu LM, Sun J, Shen WD. The change of the properties of acrylic-based polyurethane via addition of nano-silica. Progress in Organic Coatings. 2002; 45:33–42. Google Scholar

Baral D, De PP, Nando GB. Thermal characterization of micafilled thermoplastic polyurethane composites. Polymer Degradation and Stability. 1999; 65:47–51. Google Scholar

Lu H, Obeng Y, Richardson KA. Applicability of dynamic mechanical analysis for CMP polyurethane pad studies. Materials Characterization. 2003; 49:177– 186. Google Scholar

Crawford DM, Escarsega JA. Dynamic mechanical analysis of novel polyurethane coating for military applications. Thermochimica Acta. 2000; 357-358:161-168. Google Scholar

Datta J, Rohn M. Thermal properties of polyurethanes synthesized using waste polyurethane foam glycolysates. Journal of Thermal Analysis and Calorimetry. 2007; 88(2):437–440. Google Scholar

www.perkinelmer.com accessed 16.08.2019 Google Scholar

Narine SS, Kong X, Bouzidi L, Sporns P. Physical properties of polyurethanes produced from polyols from seed oils: I. Elastomers. Journal of American Oil Chemists’ Society. 2007; 84:55–63. Google Scholar

Mothe CG, Araujo CR. Properties of polyurethane elastomers and composites by thermal analysis. Thermochimica Acta. 2000; 357-358:321-325. Google Scholar

Bahattab MA, Donate-Robles J, Garcia-Pacios V, Martin-Martinez JM. Characterization of polyurethane adhesives containing nanosilicas of different particle size. International Journal of Adhesion & Adhesives. 2011; 31:97–103. Google Scholar

Zaretsky E, Asaf Z, Ran Aizik EF. Impact response of high density flexible polyurethane foam. International Journal of Impact Engineering. 2012; 39(1):1-7. Google Scholar

Grellmann W, Seidler S. Polymer testing. Cincinnati, Ohio; Hanser Gardner Publications 2007. Google Scholar

Pobrania

Opublikowane

Jak cytować

Numer

Dział

Licencja

Prawa autorskie (c) 2019 Państwowa Wyższa Szkoła Zawodowa w Tarnowie & Autorzy

Utwór dostępny jest na licencji Creative Commons Uznanie autorstwa – Użycie niekomercyjne 4.0 Międzynarodowe.