The influence of sterilization on properties of polyurethane / polylactide blend

DOI:

https://doi.org/10.5604/01.3001.0012.1264Keywords:

sterilization, surface, biodegradable polymer, topography, morphologyAbstract

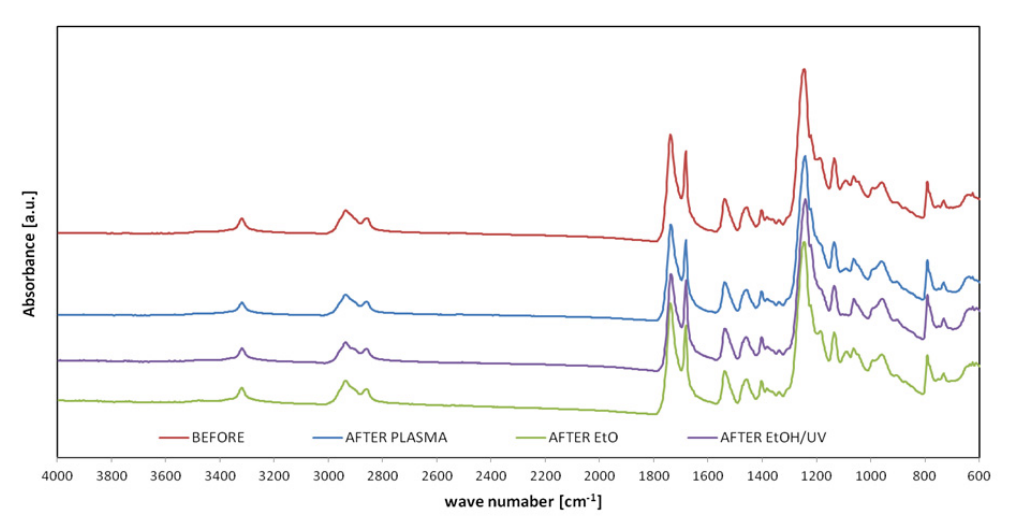

The biodegradable polyurethane/polylactide blend was treated with low temperature hydrogen peroxide plasma, ethylene oxide and immersing in ethanol combined with ultraviolet radiation. The samples sterilized by hydrogen peroxide and ethylene oxide stood practically unaffected, while UV/EtOH caused distinct changes in their mechanical properties. For example the signifficant reduction of tensile strength occured, elongation at break became twice lower, while the Young's modulus increased by 23%. The XPS measurements showed that after all types of treatment atomic carbon and nitrogen concentrations in the surface layer was slightly lower than in the bulk. Instead the surface layer was more enriched with oxygen. Ethylene oxide sterilization caused that both surfaces became more hydrophobic i.e. the contact angle increased about 15% for the top surface and 8% for the bottom surface, respectively. Sterilization with ethanol and UV radiation changed the nature of surface into more hydrophilic, the contact angle of the top surface was reduced about 6% and the bottom about 24%. The FT-IR spectra of all sterilized samples were recorded and discussed. From all used sterilization methods only hydrogen peroxide plasma is fully suitable for biodegradable PU/PLA blend.

Downloads

References

Gorna K, Gogolewski S, Mainili Varlet P. The effect of thermal treatment on sterility, molecular and mechanical properties of various polylactides. 2. Poly(L/D – lactide) and poly(L/DL – lactide). Biomaterials 1997; 18:251-255. Google Scholar

Kyriacos AA, Niederauer GG, Agrawal CM. Sterilization, toxicity, biocompatibility and clinical applications of polylactic acid/polyglycolic acid copolymers. Biomaterials 1996;17: 93-102. Google Scholar

Edlund U, Albertsson AC, Singh SK, Fogelberg BO, Lundgren I. Sterilization, storage stability and in vivo biocompatibility of poly(trimethylene carbonate)/poly(adipic anhydride) blends. Biomaterials 2000; 21(9):945–955. Google Scholar

da Silva Aquino KA, Adrovic F, editor. Sterilization by Gamma Irradiation. Gamma Radiation. In Tech, 2012. Google Scholar

Henn GG, Birkinshaw C, Buggy MA. Comparison of the effects of γ-irradiation and ethylene oxide sterilization on the properties of compression moulded poly-d,l-lactide. J Mater Sci: Mater Med 1996;7:591–595. Google Scholar

Henn GG, Birkinshaw C, Buggy M, Jones E. Evaluation of poly-DL-lactide bio-absorbable intramedullary plugs. Polym Degrad Stab 1998;61:375-82 Google Scholar

Nugroho P, Mitomo H, Yoshii F, Kume T. Degradation of poly (l-lactic acid) by γ-irradiation. Polym Degrad Stab 2001;72:337–343. Google Scholar

Hooper K, Cox D, Kohn J. Comparison of the effect of ethylene oxide and γ-irradiation on selected tyrosine-derived polycarbonates and poly(l-lactic acid). J Appl Polym Sci 1997;63: 1499–1510. Google Scholar

Gogolewski S, Mainili-Varlet P. The effect of thermal treatment on sterility, molecular and mechanical properties of various polylactides. Biomaterials 1996; 17:523-528. Google Scholar

Moreira AJ, Mansano RD, de Jesus Andreoli Pinto T, Ruas R, da Silva Zambon L, Valero da Silva M, Verdonck PB. Sterilization by oxygen plasma. App. Surf. Sci. 2004; 235(1–2):151–155. Google Scholar

Mendes GCC, Brandão TRS, Silva CLM. Ethylene oxide sterilization of medical devices: A review. Am. J. Infection Control 2007; 35(9):574–581. Google Scholar

Moisan M, Barbeau J, Crevier MC, Pelletier J, Philip N, Saoudi B. Plasma sterilization. Methods and mechanisms. Pure Appl. Chem. 2002;74(3):349-358. Google Scholar

Lerouge S, Wertheimer MR, Marchard R, Tabrizian M, Yahia L’H. Effect of gas composition on spore moratlity and etching during low-pressure plasma sterilization. J. Biomedical Mater. Res. 2000;51(1):128–135. Google Scholar

Lerouge S, Wertheimer MR, Yahia L’H. Plasma Sterilization: A review of parameters mechanism and limitation. Plasmas and Polymers. 2001;6(3):175-188. Google Scholar

Moisan M, Barbeau J, Moreau S, Pelletier J, Tabrizian M & Yahia, L. Low-temperature sterilization using gas plasmas: a review of the experiments and an analysis of the inactivation mechanisms. Inter. J. Pharmaceutics. 2001; 226(1): 1-21. Google Scholar

Gogolewski S, Mainil-Varlet P, Dillon J. Sterility, mechanical properties, and molecular stability of polilactide internal-fixation devices treated with low-temperature plasmas. J. Biomed Mater Res 1996;32:227-235. Google Scholar

Bor Y, Alin J, Hakkarainen M. Electrospray ionization-mass spectrometry analysis reveals migration of cyclic lactide oligomers from polylactide packaging in contact with ethanolic food simulant. Packaging Tech. & Sci. 2012; 25(7): 427-433. Google Scholar

Peniston SJ, Choi SJ. Effect of sterilization on the physicochemical properties of molded poly(L-lactic acid). J Biomed Mater Res B Appl Biomater. 2007; 80(1):67-77. Google Scholar

Hans J, Griesser RC, Chatelieb TR, Gengenbach GJ, Steele JG. Growth of human cells on plasma polymers: Putative role of amine and amide groups. J. Biomater. Sci. Polymer Edition 1994; 5(6):531-554. Google Scholar

Anderws KD, Kunt JA, Black RA. Effects of sterilization method on surface topography and in vitro cell behaviour of electrostatically spun scaffolds. Biomater. 2007; 28:1014-1026 Google Scholar

Gorna K, Gogolewski S. In vitro degradation of novel medical biodegradable aliphatic polyurethanes based on ε-caprolactone and Pluronics® with various hydrophilicities. Polym. Degrad. Stab. 2002; 75:113-122 Google Scholar

Pamuła E, Błażewicz M, Paluszkiewicz C, Dobrzyński P. FTIR study of degradation products of aliphatic polyesters – carbon fibres composites, J. Mol. Structure 2001; 596: 69-75. Google Scholar

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2018 University of Applied Sciences in Tarnow, Poland & Authors

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.