Engineering polymers with high mechanical and thermal resistance for electric motors

DOI:

https://doi.org/10.5604/01.3001.0010.7553Słowa kluczowe:

high-performance polymers, high thermal conductivity, electric motors materials, PEEK PAI PPSAbstrakt

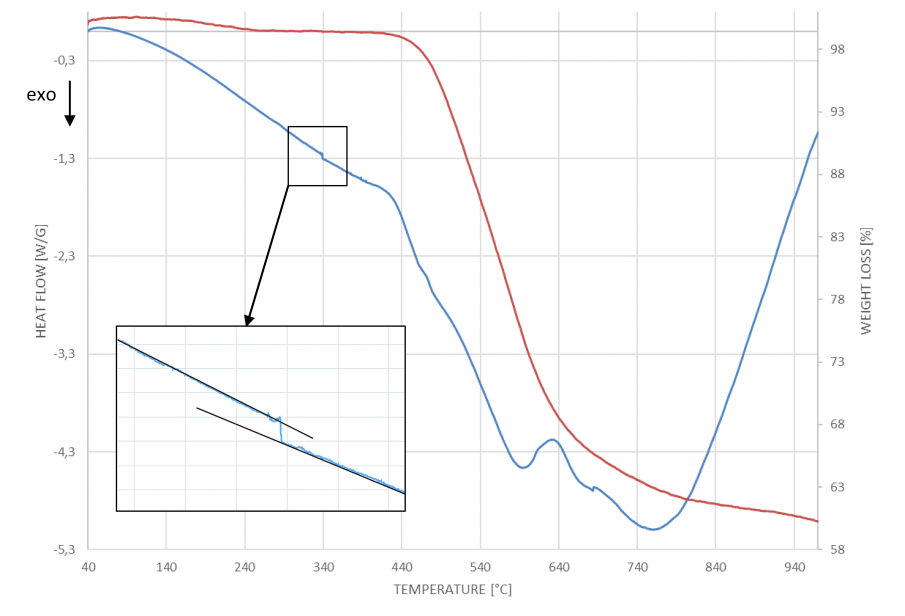

The aim of the research was to select and evaluate polymers that could be used as rotor insulation in electric motors based on Halbach array system. Which have specific material properties, such as high mechanical strength, high thermal resistance and, especially, high thermal conductivity, also at room and at elevated temperatures. Three high performance polymers were selected for the research: polyetheretherketone (PEEK), polyamideimide (PAI) and poly(p-phenylene sulphide) (PPS). Polymers were evaluated for mechanical strength, thermal conductivity, thermal diffusivity, specific heat capacity, linear thermal expansion and also differential scanning calorimetry (DSC) and thermal gravimetry (TG) analyses were carried out. Analyses are proved that all materials have appropriate properties for advanced electric motor insulator.

Statystyka pobrań

Bibliografia

M.J. Picazo-Ródenas, R. Royo, J. Antonino-Daviu, J. Roger-Folch, Eng. Fail. Anal., 2013, 35, 178–192. Google Scholar

K. Kim, J. Kim, Polymer, 2016, 101, 168–175. Google Scholar

O. Shimizu, Temperature Classes of Electrical Insulators, Three Bond Technical News, Issued December 1, 1985. Google Scholar

International Electrotechnical Commission International Standards IEC 60085-2007 – Electrical Insulation – Thermal evaluation and designation. Google Scholar

W. Martienssen, H. Warlimont, Springer Handbook of Condensed Matter and Materials Data, Springer Handbooks, 2005. Google Scholar

Hitachi Metals, Magnet wire, selection and Use Directions for Magnet Wire https://www.hitachi-metals.co.jp. (accessed October 2017). Google Scholar

S. Wang, Y. Li, Y-Z. Li, J. Wang, X. Xiao, W. Guo, Exp. Therm. Fluid. Sci., 2017, 81, 9–20. Google Scholar

H. Chen, V. Ginzburg, J. Yang, Y. Yang, W. Liu, Y. Huang, L. Du, B. Chen, Prog. Polym. Sci., 2016, 59, 41–85. Google Scholar

ASTM D 2307: Standard Test Method for Thermal Endurance of Film-Insulated Round Magnet Wire. Google Scholar

Quadrant Plastics Catalogue http://www.quadrantplastics.com/. (accessed October 2017). Google Scholar

Z. Han, A. Fina, Prog. Polym. Sci., 2011, 36, 914–944. Google Scholar

Engineers Edge Catalogue http://www.engineersedge.com. (accessed October 2017). Google Scholar

G. Wypych, Handbook of Polymers, ChemTec Publishing, 2012. Google Scholar

K. F. Johannes, High Performance Polymers (Second Edition), A volume in Plastics Design Library, 2014. Google Scholar

E. M. James, Physical Properties of Polymers Handbook, 2007. Google Scholar

K. Kim, J. Kim, Compos. Sci. Technol., 2016, 134, 209–216. Google Scholar

T. Kang, J. H. Lee, S-G. Oh, J. Ind. Eng. Chem., 2017, 46, 289–297. Google Scholar

W. N. dos Santos, P. Mummery, A. Wallwork, Polym. Test., 2005, 24, 628–634. Google Scholar

W. M. dos Santos, J. A. de Sousa, JR. R. Gregorio, Polym. Test., 2013, 32, 987–994. Google Scholar

Pobrania

Opublikowane

Jak cytować

Numer

Dział

Licencja

Prawa autorskie (c) 2017 Państwowa Wyższa Szkoła Zawodowa w Tarnowie & Autorzy

Utwór dostępny jest na licencji Creative Commons Uznanie autorstwa – Użycie niekomercyjne 4.0 Międzynarodowe.