The lightweight composite material design for automotive industry

DOI:

https://doi.org/10.55225/sti.508Keywords:

composites, automotive industry, design of composite structuresAbstract

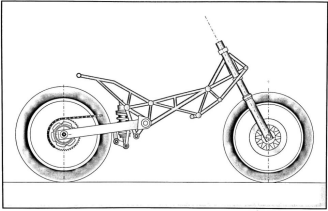

The article presents the concept of a glass fiber reinforced composite in an epoxy matrix that can be used in a motorcycle frame. Motorcycle frames types enabling the composites usage were analyzed. Composite material samples with different glass fibers orientations were produced using the pin method. The manufactured composite material was subjected to physicochemical tests to determine basic strength properties, density, work of destruction, and microscopic observation was carried out.

Downloads

References

Ashby MF. Materials Selection in Mechanical. 4th ed. Burlington: Butterworth-Heinemann; 2011. DOI: https://doi.org/10.1016/B978-1-85617-663-7.00005-9 Google Scholar

Ashby MF, Jones DRH. Materiały inżynierskie. [T.] 1. Właściwości i zastosowania. Warszawa: Wydawnictwo Naukowo-Techniczne; 1995. Google Scholar

Ashby MF, Jones DRH. Jones, Materiały inżynierskie. T. 2. Kształtowanie struktury i właściwości, dobór materiałów, dobór materiałów. Warszawa: Wydawnictwo Naukowo-Techniczne; 1995. Google Scholar

Ashby M, Shercliff H, Cebon D. Inżynieria materiałowa. T. 1. Łódź: Wydawnictwo Galaktyka; 2011. Google Scholar

Cocco G. Motorcycle Design and Technology: How and Why. Milan: Giorgio Nada; 2013 Google Scholar

Feraboli P, Masini A, Taraborrelli L, Pivetti A. Integrated development of CFRP structures for a topless high performance vehicle. Composite Structures. 2007;78(4): 495–506. https://doi.org/10.1016/j.compstruct.2005.11.011. DOI: https://doi.org/10.1016/j.compstruct.2005.11.011 Google Scholar

Liu Q, Xing H, Ju Y, Ou Z, Li Q. Quasi-static axial crushing and transverse bending of double hat shaped CFRP tubes. Composite Structures. 2014;117:1–11. https://doi.org/10.1016/j.compstruct.2014.06.024. DOI: https://doi.org/10.1016/j.compstruct.2014.06.024 Google Scholar

O’Dea N. Motorcycle swingarm redesigned in carbon composite. Reinforced Plastics. 2011;55(6):36–41. https://doi.org/10.1016/S0034-3617(11)70184-9. DOI: https://doi.org/10.1016/S0034-3617(11)70184-9 Google Scholar

Foale T. Motorcycle Handling and Chassis Design: The Art and Science. 2nd ed. [S.l.]: Tony Foale; 2006. Google Scholar

Cossalter V. Motorcycle Dynamics. 2nd ed. [S.l.]: Lulu Com; 2006. Google Scholar

Sathishkumar TP, Satheeshkumar S, Naveen J. Glass fiber-reinforced polymer composites: A review. Journal of Reinforced Plastics and Composites. 2014;33(13):1258–1275. https://doi.org/10.1177/0731684414530790. DOI: https://doi.org/10.1177/0731684414530790 Google Scholar

Morgan P. Properties of carbon fibers. In: Morgan P, editor. Carbon Fibers and Their Composites. Boca Raton: Taylor & Francis; 2005. DOI: https://doi.org/10.1201/9781420028744 Google Scholar

Fejdyś M, Łandwijt M. Włókna techniczne wzmacniające materiały kompozytowe. Techniczne Wyroby Włókiennicze. 2010;18(1/2):12–22. Google Scholar

Massalski J, Massalska M. Fizyka dla inżynierów. Cz. 1. Fizyka klasyczna. Warszawa: Wydawnictwo WNT; 2012. Google Scholar

Halliday D, Resnick R, Walker J. Fizyka dla inżynierów. Cz. 2. Fizyka współczesna. Warszawa: Wydawnictwo WNT; 2013. Google Scholar

Bowles KJ, Frimpong S. Relationship Between Voids and Interlaminar Shear Strength of Polymer Matrix Composites. San Diego: NASA; 1991. Google Scholar

Dobrzański LA. Materiały inżynierskie i projektowanie materiałowe. Warszawa: Wydawnictwo WNT; 2006. Google Scholar

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Katarzyna Suchorowiec, Piotr Szatkowski, Ewa Szczepanik, Rafał Twaróg, Michał Kisilewicz, Jacek Gralewski

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.